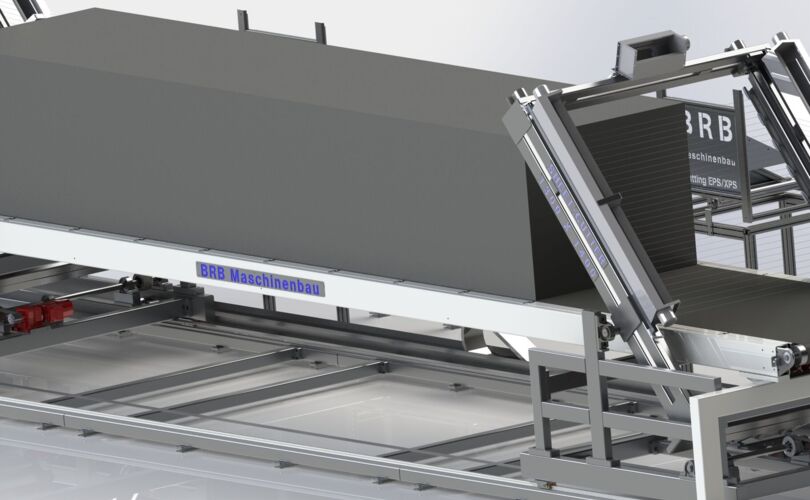

Cutting systems XPS/EPS

Cutting systems for EPS/XPS

The production of foam blocks is almost always followed by a cutting process in which the blocks are trimmed and cut to the desired plate dimensions. Our modern cutting systems work with oscillating, heated cutting wires. This enables low-loss and precise cuts.

- Block feed manually or using a tilting device with a block magazine

- Block alignment by block stop or pneumatic cylinder

- Exact block transport by chain conveyor

- Motorized tilting cutting frame up to 20 ° for panel cutting

- Quickly exchangeable cutting frames for large plate thickness ranges or with automatic wire adjustment

- Low power consumption due to opposing oscillation in the plate cutter on one level

- Infinitely variable cutting speeds

- Very little cutting loss with oscillator cut

- Accelerator belt controlled by light barriers

- Noiseless and vibration-free oscillation of the cutting wires

- Cross cutter works alternately in both directions

- Air cooling of all cutting wires

- High cutting speed with oscillator cut

- Automatic alignment devices in the cross cutter

- Primary crusher for upper rind with suction device

- Central rind crusher for side, bottom and forehead rinds

Contact person for EPS/XPS

Managing Director

B.-Eng.

Lars Brüggemann

Phone. +49 (0) 25 72 / 96 709 - 30

E-Mail lars.brueggemann@brb-emsdetten.de